Low-frequency sound waves (20–80 Hz) in compact clubs face unique obstacles. At 40 Hz, wavelengths exceed 28 feet—larger than most small venue dimensions—creating standing waves that amplify or cancel bass energy. Common issues include:

18-inch subwoofers address these challenges through superior air displacement efficiency. Larger cone surfaces produce 3–5 dB greater output than 15-inch models at equal power levels, enabling sound engineers to maintain headroom while reducing distortion.

The physics of large drivers inherently combats small-room acoustics:

In a 2022 study comparing sub sizes in 1,500 sq. ft. venues, dual 18-inch models achieved 32% more uniform bass distribution (±2.1 dB variance vs. ±3.8 dB for 15-inch equivalents).

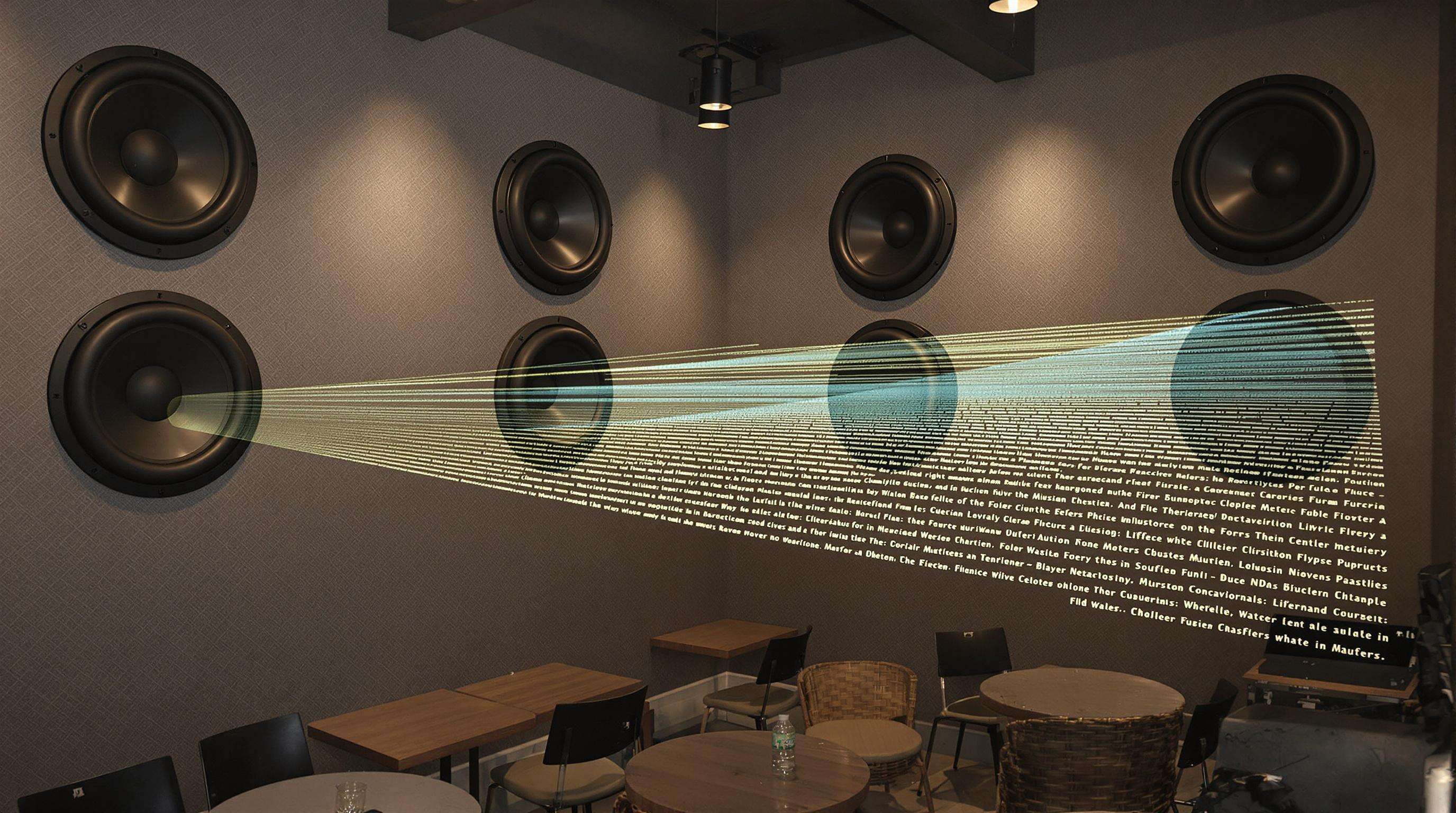

A London basement venue (1,800 sq. ft.) transformed its bass reproduction using three key 18-inch subwoofer strategies:

| Technique | Result | Measurement |

|---|---|---|

| Cardioid array formation | 14 dB rear attenuation | 38 Hz @ 105 dB SPL (C-weighted) |

| Corner loading | +6 dB LF extension | 28 Hz (-3 dB point achieved) |

| Asymmetric placement | 58% reduction in null zones | LFCam spatial analysis map |

Post-installation surveys showed 87% of attendees reported improved bass clarity. The system now delivers 126 dB peak SPLs while maintaining <1.8% THD at 35 Hz.

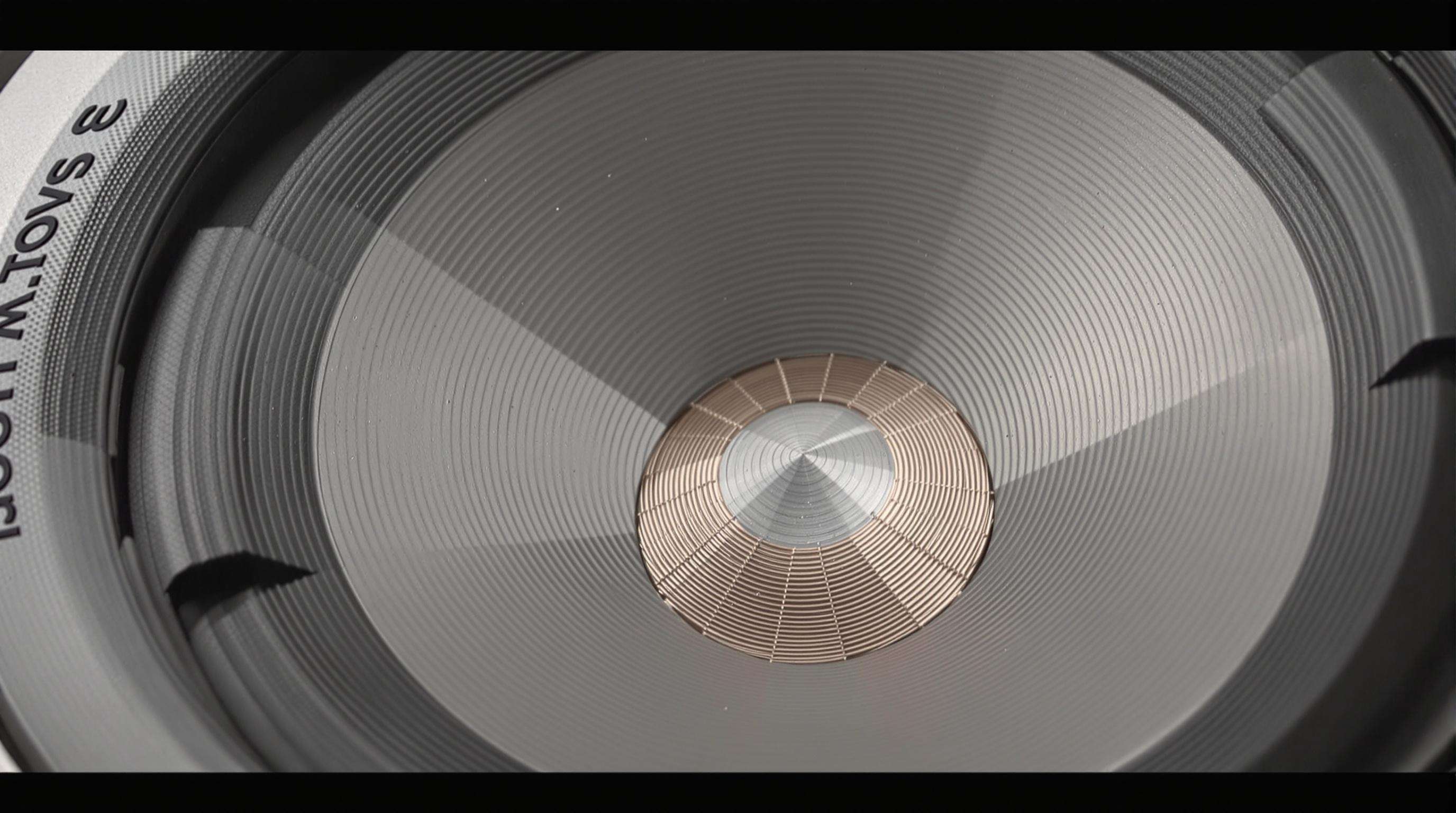

Modern 18-inch subwoofers leverage dual-layer edge-wound voice coils to withstand sustained power inputs exceeding 2,000 watts. These combine copper-clad aluminum windings—offering 24% better thermal conductivity than pure copper—with symmetrical magnetic gap geometries that reduce harmonic distortion by 18 dB at maximum excursion.

Engineers now deploy multi-layered composite diaphragms combining:

This construction achieves a 17 Hz lower resonance frequency compared to paper cones while maintaining 92% rigidity at 35mm peak-to-peak excursion.

High-efficiency 18-inch subwoofers incorporate three-stage cooling systems:

These mechanisms enable 96-hour MTBF in 35°C ambient environments—a 300% reliability increase over previous generations.

Front-firing designs direct energy toward the audience zone while down-firing configurations reduce structural vibrations. Front-facing 18-inch subs achieve 12% higher SPL at 40 Hz in rooms under 500 sq ft, but down-firing systems show 18% fewer ceiling standing wave issues.

Stacking two units vertically yields a 6 dB output boost, while horizontal arrays spaced ¼ wavelength apart create coherent wavefronts. Cardioid arrays using three 18-inch subs reduced rear-wall cancellations by 21 dB in 200-capacity rooms.

A 300-person venue deployed two front-firing 18-inch subs angled 30° inward, with a third down-firing sub under the DJ booth. This achieved:

| Frequency Range | Seat-to-Seat Variance |

|---|---|

| 30–50 Hz | ±1.5 dB |

| 50–80 Hz | ±2.1 dB |

| Driver Size | Frequency Response (Hz) | Max SPL (1m) |

|---|---|---|

| 12-inch | 45 - 150 | 126 dB |

| 15-inch | 38 - 120 | 129 dB |

| 18-inch | 25 - 100 | 132 dB |

| Metric | 12-inch | 15-inch | 18-inch |

|---|---|---|---|

| Sensitivity (1W/1m) | 89 dB | 93 dB | 97 dB |

| Power Required for 120dB SPL | 800W | 500W | 200W |

Fourth-order Linkwitz-Riley crossovers with 24 dB/octave slopes ensure phase coherence with main speakers. DSP platforms enable:

Modern amplifiers using Dante/AES67 protocols allow 18-inch subs to operate as intelligent bass nodes. Real-time monitoring tracks:

These systems reduce clipping-related distortion by 41% while extending driver lifespan.

18-inch subwoofers are preferred due to their ability to efficiently displace air, producing greater output and minimizing sound distortions, even at high SPLs. Their larger cone surfaces help combat challenges like standing waves and null zones commonly found in small venues.

Their design enhances directional control and wavelength matching, thus reducing modal excitation and improving bass distribution by overcoming obstacles like modal resonance.

Modern subwoofers use advanced materials like dual-layer voice coils and multi-layer composite diaphragms for enhanced performance and durability, maintaining high rigidity and lowering resonance frequencies.

Advanced cooling systems, such as vented pole pieces and phase-change materials, effectively manage heat, providing increased reliability and power handling capabilities in continuous-duty applications.